Fast-PCB provide small batch, multi-species, high-quality electronics manufacturing services to customers in industrial control, medical, automotive, communications, new energy, and high-end consumer products. We help our customers make the world a better place.

We are now actively promoting the company's global presence as well as digitalization process, and have already established bases in Shanghai, Chengdu, etc.

Our vision is to please our customers so well that our services will be their first choice.

Our aim is to be a global leader in high-quality, versatile, and flexible high-end EMS industry.

Our vision is local company with global commitment.

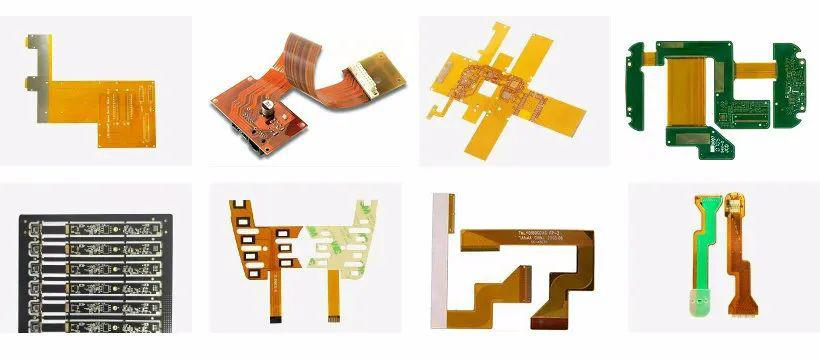

1.Product and service Introduction of SMT

We provide customers with one-stop services in the electronics field .

Our assembly process, have been managed to create high-quality electronic products with “prototype to volume, high mix and high value” by combining our advanced management system with state-of-the-art equipment.

We’re well-equipped production lines with facilities and machines imported from Japan and Germany, such as automatic solder printing, high-precision placement machines, lead free hot air reflow machine, selective wave soldering machine, AOI inspecting machine, infrared BGA repair station. With the one-up machines we are in capable of providing serial services, such as component mounting , testing, maintenance, assembly, aging, packaging for your electronic products, with 70,000 mounting points per hour per SMT machine and 400M mounting points per year。

We can provide our support in accompany with customers product design, new product

prototype to mass production, and to grow up with our customers.

2.Product Parameter (Specification) of SMT

Panel 550*650mm max | Thickness 6mm max | QTY 6500SMD/Panel

| Complexity Double Sided、Packaging、Testing、DIP、FPC and Rigid-Flex |

ICT/FCT/AOI/X-Ray Yes |

3.Product Feature And Application of SMT

Whether you are looking to introduce new products to the market, upgrade legacy products, achieve cost requirements, or meet regulations, Benchmark offers end-to-end, comprehensive manufacturing services.

Fast-PCB’s manufacturing facilities are strategically located throughout the globe, which allows us to develop intimate relationships with our customers and work closely with you to solve complex challenges. We also leverage our global supply chain to manage materials and components, bringing products to market faster and more cost-effectively.

Our manufacturing process is supported by our industry-leading, data-driven quality management system. This allows us to guarantee high quality and reliability, maintain strict regulatory compliance, and deliver products on schedule. Our customer focus teams provide frequent communication, leveraging product dashboards and customer self-service portals.

4.Product Details of SMT

Fast-PCB can support flexible printed circuit SMT, which has different requiements, we could follow IPC-A-610、J-STD-001、MIL-STD-2000、GB, etc.

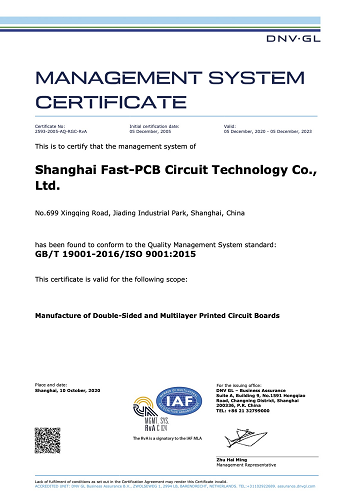

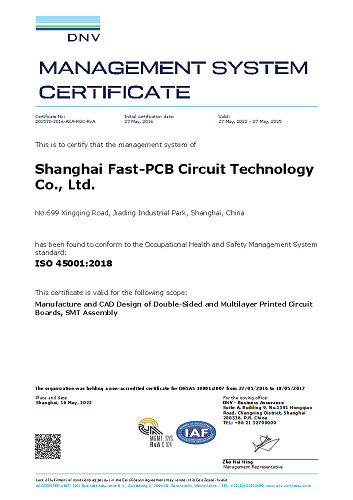

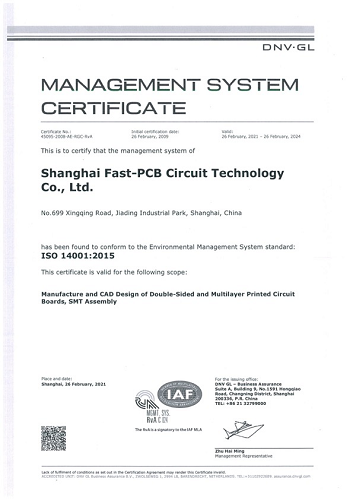

5. Product Qualification of SMT

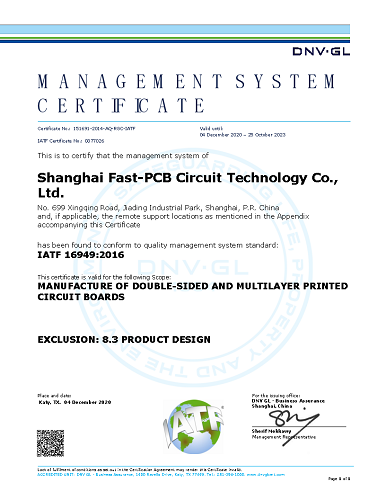

Fast-PCB is certified by ISO 9001:2015, ISO 14001:2015, ISO 45001:2018,

IATF 16949:2016 and registered with US and Canada UL,

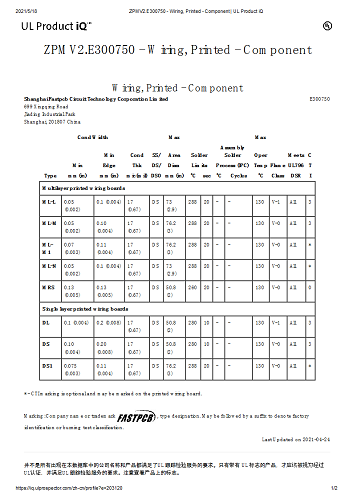

E300750 - Wiring, Printed - Rigid

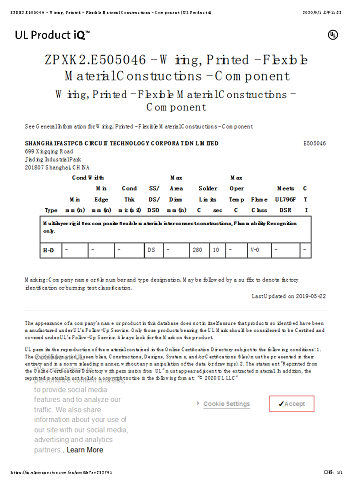

E505046 - Wiring, Printed - Flexible

6.Deliver,Shipping And Serving of SMT

We can dispatch goods via different express companies, like DHL, UPS, TNT and FedEx.

If the customer has dedicated forwarder, we can support ex-works delivery term as well.

7.Company Introduction

Fast PCB is located in the Jiading Industrial Zone of Shanghai. Since its establishment in April 2004, it has been committed to the production, manufacturing, and research and development services of high-precision, medium and small batch, and fast printed circuit boards, providing professional, reliable, efficient, and high-quality services for domestic and foreign high-tech enterprises and research institutions. The company covers an area of 28000 square meters, with a factory area of approximately 27000 square meters.

The company team has industry-leading experience in small and medium-sized batch and sample manufacturing of printed circuit boards, quickly providing high-quality high-tech products, widely used in various fields such as communication, industrial control, computer applications, aerospace, medical, automotive, testing instruments, etc. Our expertise lies in the management of multiple varieties, small and medium-sized batch rapid production models.