mSAP PCB

1.Product and service Introduction of mSAP PCB

mSAP technology enables the production of printed circuit boards and IC substrates of a size and complexity that almost rivals products from the semi-conductor industry. mSAP stands for “modified semi-additive process” – a technology in which the conducting paths used to conduct signals on a printed circuit board or substrate are not etched out of a copper layer in the usual way. Instead, the conductive material is only applied to the PCB in places where it is actually needed. Unlike the conventional method, this makes for significantly tighter signal lines and smaller distances between the conducting paths, we have very good cooperation relationship with almost the popular express companies like DHL, UPS, TNT and FedEx.

2.Product Parameter (Specification) of mSAP PCB

Layer Count: 40 Max. | Material: Mid and high Tg, High Speed or high frequency, Resistance/Capacitance embedded, etc. | MicroVia: 0.075um min. | Surface Treatment: HASL, HASL Lead Free, ENIG, ENEPIG, IAg, ISn, Flash Gold, Gold Plating, OSP, etc |

Solder Mask: Green White Black Yellow Blue Red Etc. | Silkscreen: Green White Black Yellow Gray Etc. | Line/Space: 0.075/0.075 um min. | Reliability: 100% Electrical Test 4-wire Test Impedance Test RoHS Test Thermal Stress Test High Voltage Insulation Resistance Test Ionic Contamination Test Solderability Test Microsection Analysis Insulation Resiatance Test Peel-off Strength Test Dielectric Loss Test Etc. |

3.Product Feature And Application of mSAP PCB

Benefits of mSAP technology

· mSAP saves space as it allows denser conducting path layouts. This opens the way for the miniaturisation of PCBs and devices.

· Short signal paths enhance signal transmission on the PCB.

· mSAP offers better performance at a smaller size.

· Radically thin PCBs for radically thin devices.

· mSAP shrinks PCBs, freeing up space for sensors, cameras and larger batteries.

4.Product Details of mSAP PCB

Fast-PCB can fabricate diverse mSAP PCB prototypes, which has fine line and narrow space designed, we could follow class 3 of IPC 6016.

mSAP provides another boost to miniaturisation for the electronics industry, as circuits can be planned and executed in exceedingly compact spaces, thanks to their smaller structural dimensions. It also reduces the risk of short circuits on densely packed circuit boards, because (unlike their chemically created counterparts) mSAP conducting paths do not extend across the base. This means that although the distances between them are small, there is no risk of signal interference.

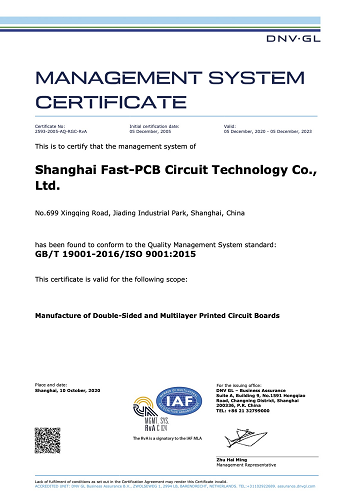

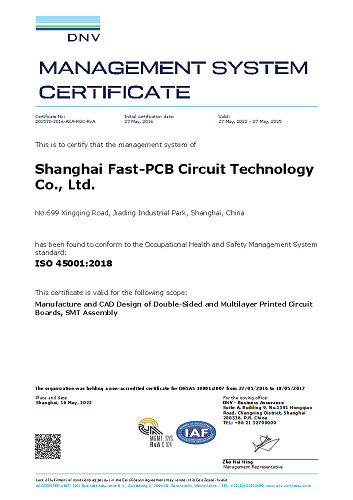

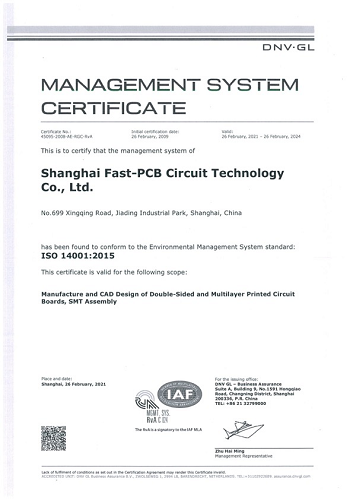

5.Product Qualification of mSAP PCB

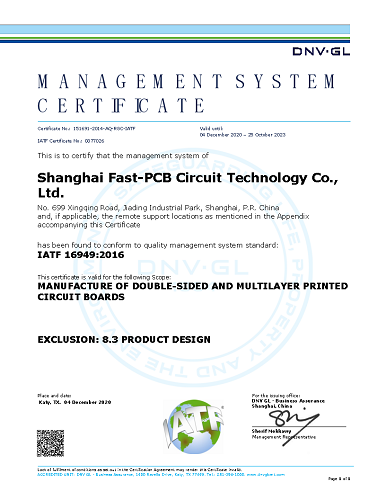

Fast-PCB is certified by ISO 9001:2015, ISO 14001:2015, ISO 45001:2018,

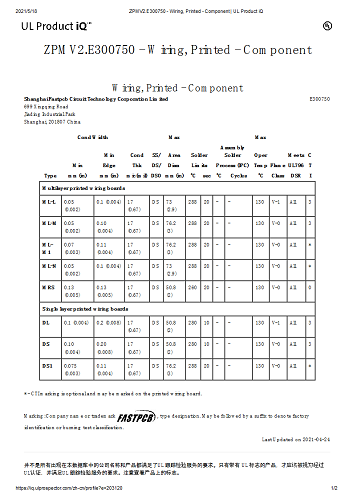

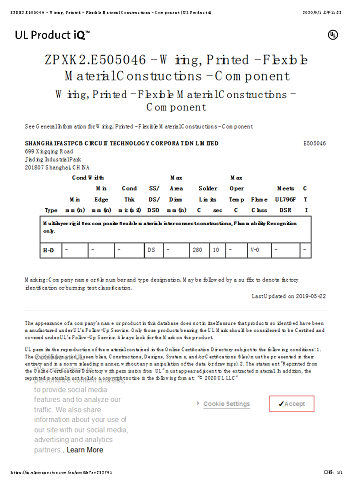

IATF 16949:2016 and registered with US and Canada UL,

E300750 - Wiring, Printed - Rigid

E505046 - Wiring, Printed - Flexible

6.Deliver,Shipping And Serving of mSAP PCB

We can dispatch goods via different express companies, like DHL, UPS, TNT and FedEx.

If the customer has dedicated forwarder, we can support ex-works delivery term as well.

8. Company Introduction

Fast PCB is located in the Jiading Industrial Zone of Shanghai. Since its establishment in April 2004, it has been committed to the production, manufacturing, and research and development services of high-precision, medium and small batch, and fast printed circuit boards, providing professional, reliable, efficient, and high-quality services for domestic and foreign high-tech enterprises and research institutions. The company covers an area of 28000 square meters, with a factory area of approximately 27000 square meters.

The company team has industry-leading experience in small and medium-sized batch and sample manufacturing of printed circuit boards, quickly providing high-quality high-tech products, widely used in various fields such as communication, industrial control, computer applications, aerospace, medical, automotive, testing instruments, etc. Our expertise lies in the management of multiple varieties, small and medium-sized batch rapid production models.