Fast-PCB is a leading PCB prototype manufacturer in China. We have been specialized in PCBs prototype manufacturing for 20 years. Our products have a good advantage of our quick-turn-around lead time and cover most of the European and American markets. We look forward to becoming your long-term partner in China.

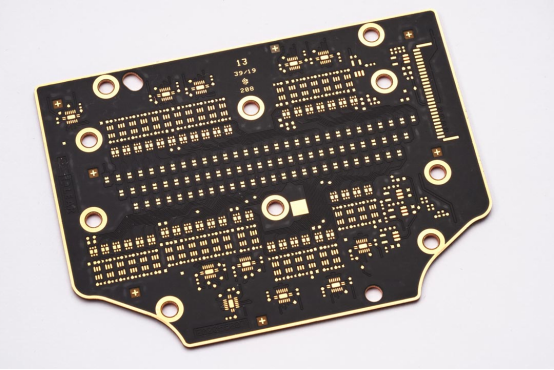

Heatsink PCB

1.Product and service Introduction of Heatsink PCB

Fast-PCB offers with solid metal reverse sides especially for heat dissipation on components with high power losses.

The IMS technology is really efficient for power electronics applications with high power dissipations and a limited layout thickness. Materials with a high thermal conductivity along with good electrical insulation were specially developed for this purpose. The full-surface, solid metal reverse side ensures fast and effective temperature spread, which prevents hotspots, we have very good cooperation relationship with almost the popular express companies like DHL, UPS, TNT and FedEx.

2.Product Parameter (Specification) of Heatsink PCB

Layer Count: 4 Max. | Material: Aluminum & copper plate. FR-4, PTFE, heat dissipation dielectric layer. | Thickness: 3.2mm Max. | Surface Treatment: HASL, HASL Lead Free, ENIG, ENEPIG, IAg, ISn, Flash Gold, Gold Plating, OSP, etc |

Solder Mask: Green White Black Yellow Blue Red Etc. | Silkscreen: Green White Black Yellow Gray Etc. | Line/Space: 0.1/0.1 um min. | Reliability: 100% Electrical Test 4-wire Test Impedance Test RoHS Test Thermal Stress Test High Voltage Insulation Resistance Test Ionic Contamination Test Solderability Test Microsection Analysis Insulation Resiatance Test Peel-off Strength Test Dielectric Loss Test Etc. |

3.Product Feature And Application of Heatsink PCB

APPLICATIONS

· LED applications

· Transducers

· Motor control

· DCB replacement

SPECIAL FEATURES

· Thermal storage capacity (at same volume): 37% higher than aluminium

· Thermal conductivity: 77% higher than aluminium

· Modulus of elasticity: 85% higher than aluminium

4.Product Details of Heatsink PCB

The usual IMS solutions on the market have aluminium reverse sides. Fast-PCB recommends the use of copper reverse sides as an alternative, since this offers significantly improved physical properties and enables more variable use. A major difference from aluminium is that copper is compatible with all PCB processes, meaning that different surface finish coatings can be used and multilayer lay-ups are possible.

5.Product Qualification of Heatsink PCB

Fast-PCB is certified by ISO 9001:2015, ISO 14001:2015, ISO 45001:2018,

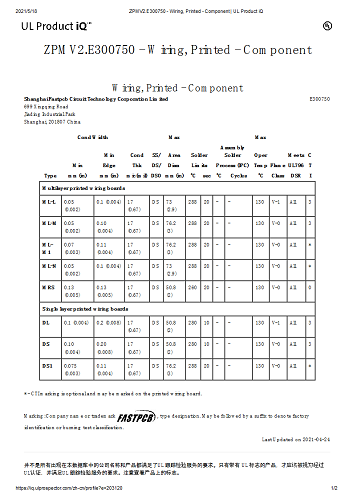

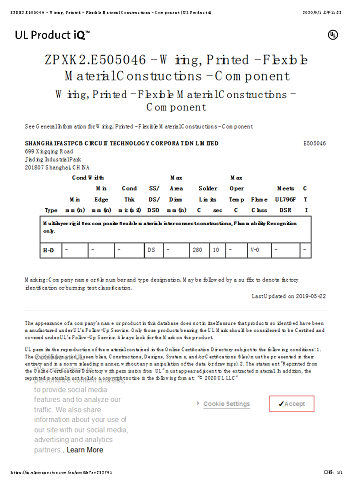

IATF 16949:2016 and registered with US and Canada UL,

E300750 - Wiring, Printed - Rigid

E505046 - Wiring, Printed - Flexible

6.Deliver,Shipping And Serving of Heatsink PCB

We can dispatch goods via different express companies, like DHL, UPS, TNT and FedEx.

If the customer has dedicated forwarder, we can support ex-works delivery term as well.

7.Company Introduction

Fast PCB is located in the Jiading Industrial Zone of Shanghai. Since its establishment in April 2004, it has been committed to the production, manufacturing, and research and development services of high-precision, medium and small batch, and fast printed circuit boards, providing professional, reliable, efficient, and high-quality services for domestic and foreign high-tech enterprises and research institutions. The company covers an area of 28000 square meters, with a factory area of approximately 27000 square meters.

The company team has industry-leading experience in small and medium-sized batch and sample manufacturing of printed circuit boards, quickly providing high-quality high-tech products, widely used in various fields such as communication, industrial control, computer applications, aerospace, medical, automotive, testing instruments, etc. Our expertise lies in the management of multiple varieties, small and medium-sized batch rapid production models.